Today was a big day in the life of our brand new building, as the concrete team finally arrived to pour the floor. 220 tonnes of concrete were being laid in one day, which is no small undertaking. Thankfully, the experts were on hand to make sure the day ran smoothly.

Pouring concrete across this huge area demands some impressive machinery. The wet concrete arrives in concrete mixers from the Smiths quarry in Banbury. Our job requires more than twenty truckloads of concrete. The concrete mixers unload unto a hopper on the back of a concrete pump, which then sucks up the concrete and sends it down a pipe at 360psi. This is paradise for machinery freaks.

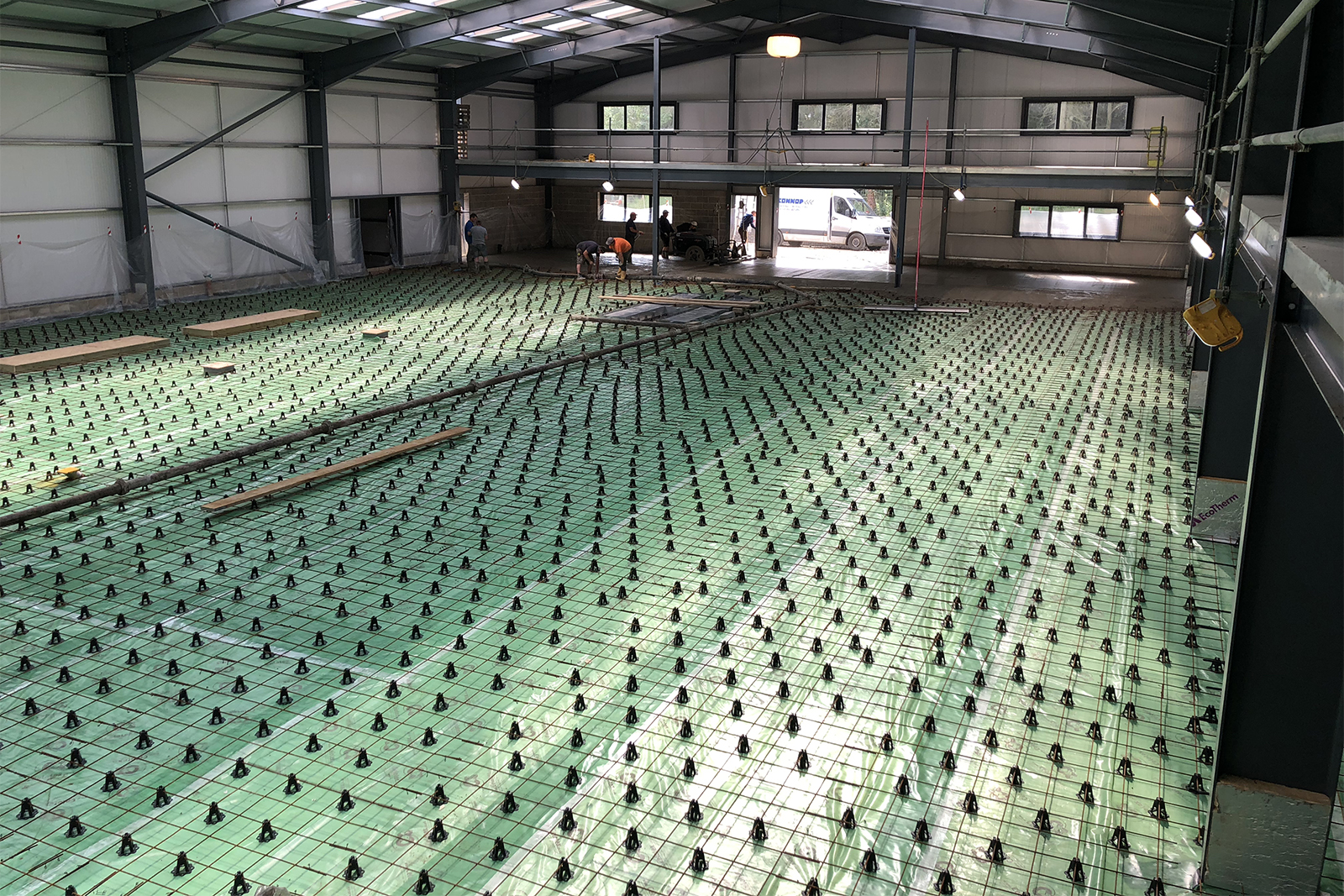

The pipe runs down an extendable boom arm off the side of the truck and is run across the steel reinforcing mesh, which is set into the new floor to add strength. Three strong men at the end of the pipe control where the flow of concrete is deposited. Once enough concrete has been poured in the right place, skilled workers tamp the wet concrete to remove any air bubbles and level the surface by hand. The excess water rises to the surface, where it can evaporate as the concrete cures.

When the concrete slab has cured enough to carry some weight, power floaters are sent on to polish the surface and give a smooth finish, ready to be painted or protected by sealer. The finished concrete surface closes off the foundations and groundworks and becomes known as the oversite. When a building reaches this stage, things are definitely on the home straight.

There is still a lot of work to do before everything is finished and the building can be occupied, but the chequered flag is definitely in sight. Exciting times!

Back to News

Back to News